A winding machine has to cope with heavy loads at high speed. Whether paper rolls for reel-fed offset printing, wallpaper rolls or carpet rolls – the machine has to make sure that no tears or disruptions occur, and the rolls must be packed densely and accurately. If a roll is full, the winder automatically moves to the next one.

The material reaches the winder at a constant speed of up to 300 meters per minute. If the roll is still small, the winder has to turn quickly; as the roll circumference gets bigger, the turning speed has to drop accordingly. With these varying conditions, it is of utmost importance that the pulling force is always constant. Only then will the material be kept from tearing or jamming.

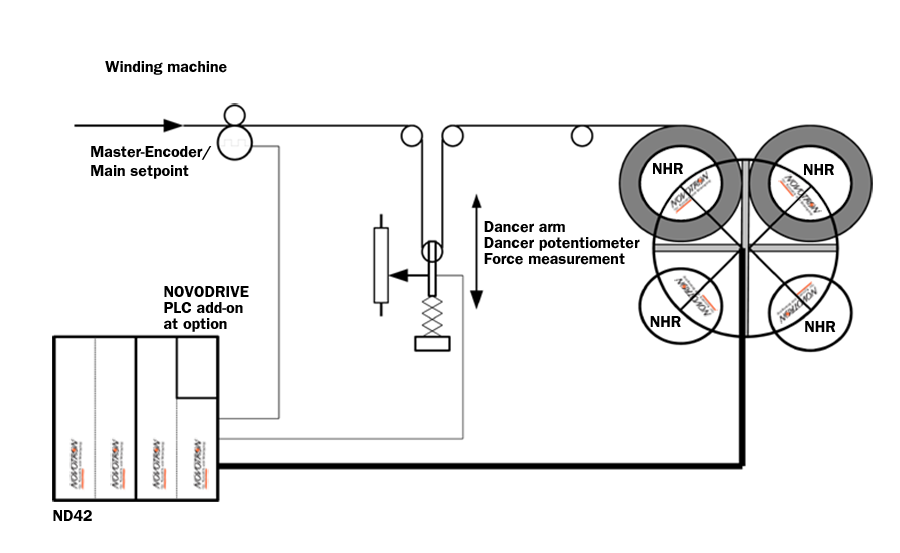

Our ND42 servo converter allows you to control the pulling force in two ways:

- direct regulation by means of force measurement or dancer arm,

- indirect regulation through current limitation.

By means of our NOVODRIVE PLC add-on, it is possible to set up a winder control, with the PLC continuously recomputing the roll diameter and controlling the speed.

Even if you have high-power requirements – the "strongest" servo inverter in our product line, the 10 kW version of ND43, will certainly do the job.